Plant Design & Management Services

Considerable experience in using PDMS (Plant Design Management System) has been achieved in design offices spanning a number of industries. The range of tasks which have been undertaken extend beyond some of the original concepts. PDMS remains the cornerstone of the mainstream process design function, but it has also been used in a stand-alone role to carry out checks on specific design aspects.

The ability to have a full process plant design built up and stored in such a way as to have ready access to any part, at any stage of the design, is now readily appreciated by design engineers. It is expected that other agencies involved in the design process, such as certification and safety authorities, will benefit from having a process design available which has been scrutinized using design compatibility routines.

All the product development, design, and manufacturing companies require an automation solution to manage and utilize the 3-D CAD design data. However, for most of them, choosing an appropriate Plant Design Management system (PDMS) is challenging. PDM, which is a design-led technology, essentially centers on maintaining design data related to the product development process. It can improve its efficiency by refining the product-related design data.

Redhan PDMS services team comprises of experienced and highly skilled draftsmen, project managers, designers, and senior engineers who help us offer timely, high-quality, and cost-effective PDMS Solutions within a quick turnaround. Our experienced engineers create the most efficient plant designs which allow our clients manufacture to different types of products with ease without facing any challenges.

Our PDMS team can provide complete plant design engineering services and has extensive work experience on many plant design management system tools such as SolidWorks PDM, CADWorx, Autodesk Vault, Teamcenter, etc.

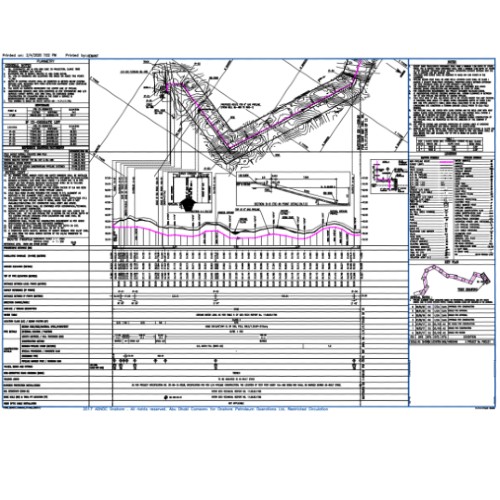

Alignment Sheets

GA of Pipeline

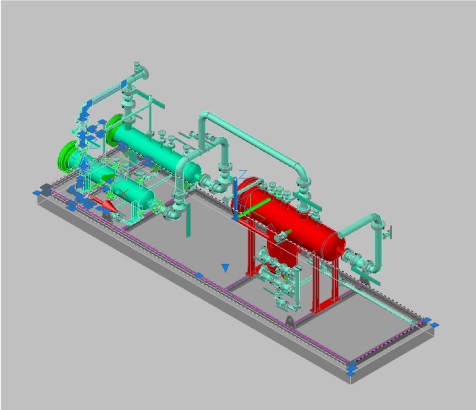

3D Modeling

Core Competencies:

Key Services Rendered:

- Piping & Equipment Layout

- 2D & 3D Modeling of Plant

- Piping Material Specification

- Valve & Specialty Item Specification Sheet

- Bill of Materials, Isometrics etc.

- Preparation of Datasheets for various piping Components

- As-Built drawings

- Procurement Assistance