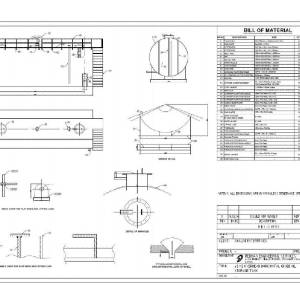

Equipment Design

Pressure Vessels Design

Many of companies are subjecting to the hazards resulted from the incorrect design and manufacturing of pressure vessels (leakage or Explosion), those used in the storage of dangerous liquids or pressurized fluids.

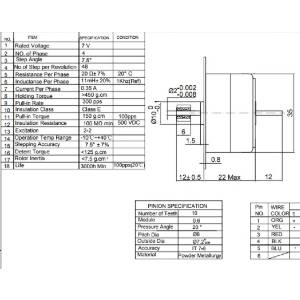

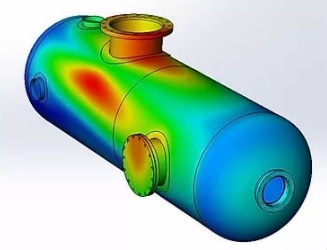

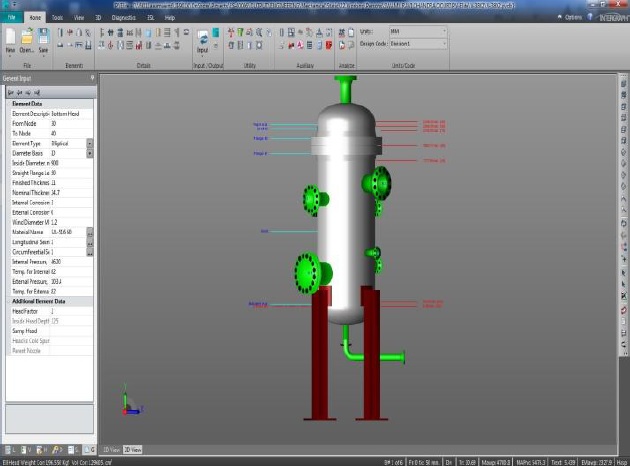

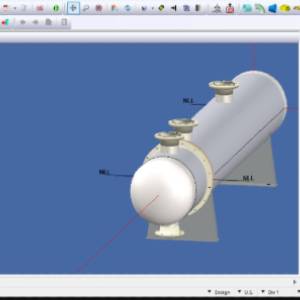

The design of vertical pressure vessel is carried out using the American Society of Mechanical Engineers (ASME) Codes. ASME section VIII and Division 1 and 2 are used in our designs. Various components of the pressure vessel are designed by calculating the appropriate design factors like thickness of the shell, head, stress analysis etc. to validate the design result the pressure vessel is modelled and analyses in Solid works software.

The first step in designing a container is choosing the best type for the service for which it is intended. The factors influencing the choice of type are the function of the container, the location, the nature of the fluid that has to be stored, the temperature and operating pressure and their ability to store the volume needed by the processes are efficiently considered in our solutions.

Storage Tanks Design

The design and maintenance of atmospheric and low pressure vessels for oil storage is becoming ever more vital as crude oil storage capacity utilisation rises and oil storage capacity grows globally. The US Energy Information Administration shows crude oil storage capacity utilisation rising steadily.

Standards for tank design from the perspective of the casual observer, these storage tanks just sit there doing their job day in, day out and then in a spark of enlightenment, questions start to pop into the minds of the curious:

- How thick do the walls and floors of these structures have to be?

- Why are some tanks bolted down to the ground and others are not?

- What internal support structures are needed if the tank has a fixed roof?

- What happens to a tank during a hurricane or earthquake?

The answers to these questions are readily available. They ultimately lie in the pages of the following codes and standards:

- American Petroleum Institute (API) 650

- BS EN 14015:2004

- API 620

Tank design codes reflect the culmination of decades of work by many dedicated individuals. Using these standards helps to ensure that tanks will be able to stand the rigours of the elements and conditions to which they are subjected.

Other Services

Heat Exchangers as per ASME and TEMA

Review of Equipments drawings/ documents